At FootingFirst™ we are always trying to explore new possibilities to improve our products. As the leader in the industry, we seek to share our knowledge with our customers to help them make educated decisions.

Our news column is dedicated to industry updates as well as education.

Ten Considerations for Building Your Dream Arena

One: Pick a Contractor

Having a reputable, experienced contractor build your arena is imperative. A contractor who has experience using the proper materials, techniques and equipment will make all the difference in the success and longevity of your arena. Gather references and as much information as possible to ensure you have selected the right contractor for the job!

We have installers throughout the US and Canada that we work with regularly to ensure that our product is being installed properly on a quality base. Fields and Footings in Massachusetts, Ballard Construction with multiple locations throughout the US, Lawton Adams Construction in Westchester County, NY, Bear Excavating of Calgary, and Marco Clay of Toronto to name a few. Contacting us for a reputable installer in your area is the first step in the process of building your dream arena!

Two: Indoor Arenas

A solid laser-graded base is the most important aspect of building any arena. The base is your foundation, which will help ensure stability and a consistent footing depth throughout your arena. Using the proper materials that achieve a high compaction makes all the difference. The correct equipment is needed to carry this out so it holds up to the wear and tear of everyday riding. There are also base matting options such as our EBUS cushion mat. The matting system enhances the base by adding forgiveness and cushion from the top layer down.

Three: Dust-Free Surfaces

We have been creating dust free footing for over 20 years. Through years of continuous research and development we have mastered each product to fit specific riding disciplines. Not only do our dust free footings create safe and durable riding surfaces, they also require minimal maintenance. No more dragging hoses, expensive irrigation systems or mag applications. Spending less time maintaining your footing allows you to spend more time doing what you love, riding. We can help you get the absolute most out of your footing. To find out which dust free product is right for you, contact us.

Four: Water-Dependent Footing

Our high-performance, water-dependent product, Superior Riding Surface (SRS), is widely used throughout the industry by many top professionals such as McLain Ward, Daniel Bluman, Alex Granato, and more. The benefit of a water-dependent product is that you are able to manipulate and dictate footing performance based on the moisture content applied. We offer different water-dependent sand/EGT fiber products, depending on the geographic location for affordability. We are also able to send our SRS throughout the country from one of our many mixing sites. A proper irrigation system is needed as these products need to be watered daily.

Five: Outdoor Arena Base

There are multiple ways to build your outdoor arena, from high tech ebb-and-flow watering systems to a traditional stone dust base with basic drainage. The most important thing is that the arena is built with the properly compacted materials at the proper grade. The two types of base we generally install are a traditional compacted stone base, or a free-draining base. A traditional stone dust base with the proper pitch is very functional and works mostly with surface drainage. Additional drainage is often added to the interior sides of the arena to direct that water elsewhere. A free-draining stone base is a loose aggregate base that is porous, so the water is able to flow straight down through the footing and base to drainage below. This drains much quicker and is more effective after a heavy rainfall. A properly constructed base with adequate drainage will keep your arena rideable throughout the year.

Six: Outdoor Arena Drainage

Ultimately, an arena is built to absorb and handle only what falls from the sky onto the arena, so drainage that captures water from the surrounding landscape is imperative. You do not want to have water entering the arena from the outside. Always look at your outdoor arena’s positioning to see where the water flows, and try to work with it as best as possible. Dry wells may be needed, curtain drains, and swales are all means of directing water away from your arena. A free-draining base arena will handle the rainfall the very best. You will not miss a day with a free draining base however, you still need good drainage within the base. Pipe needs to be installed to send the water to whichever area you have decided can handle the extra flow. We call this daylighting, and this is where the pipe will open to the grass and natural grade which will flow towards a water source like a pond, lake or a dry well. With a traditional base we add what we call interior drains and they are added close to the edge so the water flows across the arena to the drain. We often use grids over the drains to allow the water out quickly and keep the footing and the small stone separated. The intricacy of drainage is well executed by a knowledgeable installer!

Seven: Matting Systems

Matting systems for your arena have become the newest and most innovative addition to riding arenas. There are many different mats on the market currently, and all serve a different purpose.

Our EBUS mats (Equestrian Buffer Underlayment System) have been a game-changer in the world of equestrian footing. They can be installed both indoors and outdoors, and enhance the performance of our excellent footing products. Added cushion, reasonable cost, and easy installation are all benefits of these mats. Through extensive scientific testing, these mats have shown excellent results to improve your horses’ performance and reduce risk of injury.

Additionally, the OT-40 mat is an excellent mat that will help reduce concussion and improve drainage. It is useful over a free draining base outdoors, as it allows water through the mat very quickly and adds stability to your base layer. We have also found this mat especially useful in round pens and small arenas where added strength and traction may be needed. Both of these products need 5 inches loose of footing over the top to preserve your mats integrity.

Grids are another type of mat that we generally use over interior drains within the arena. They are amazing for dry paddocks, around watering systems in fields, and on any steep grade where erosion may occur. They come in a variety of shapes and sizes, but are solely used for drainage and stability, adding no concussion value to your riding arena.

Eight: Additives

European geo-textile (EGT) fiber provides traction, cushion, and water retention to footing. EGT is used in almost all of our signature pre-mixed products. For existing sand arenas, EGT can be added to help stabilize and improve performance. Traditionally it works best with finer sands and is recommended to be installed by an experienced contractor. EGT fiber is an additive, not a footing.

Rubber: We offer two types of rubber which add cushion and help loosen up compacted footing. This is one of the more cost-effective methods in amending your arena, but both EGT fiber and rubber together are superb for revitalizing an old arena. Rubber is easily added to footing, and creates voids in the sand particles so they don’t compact as much, giving a bit more spring to footing that may need some rejuvenation. We use only virgin rubber so there are no recycled materials involved. Rubber is also found in our dust-free blends TravelRight and TravelBright

Nine: Maintenance

Maintenance is a key factor in determining your footing’s performance and longevity. We have some recommendations that we encourage our clients to follow once the footing is installed and our job is done.

Grooming: “The amount of arena grooming required is dependent on the footing. A footing that compacts easily will require more dragging, which also means burning more fuel, more wear and tear on your tractor, worn out teeth on your groomer, etc. It does add up. Dust-free footing generally requires less grooming, but of course all grooming depends on use and weather.” – Lawton Adams of LAC. For water-dependent products, daily watering with harrowing is essential. We work closely with Carolina Arena Equipment who supplies us with all of our Drag-N-Fly harrows for a perfect finish.

Laser Grading: Annual laser grading by an experienced contractor is crucial. Laser grading will keep your footing at a consistent depth, protect your base, and prevent injury. Consult with your contractor during your annual laser grade to ensure you are maintaining your footing properly and to address any questions you may have.

Ten: Research

Research and asking questions will help you not only better understand the process but allow you to make the best decision on your investment. We are confident in not only our products, but our installation and maintenance crews throughout the country. We’ve tested our products thoroughly with the help of the following industry leaders in scientific testing: Mick Peterson of Racing Surfaces Testing Laboratory from the University of Kentucky; Jeffrey Thomason of Ontario Veterinarian College at University of Guelph; Sport Surfaces Testing and Consultants at Labosport who tests for FIFA and World Rugby; and Sarah Jane Hobbs University of Central Lancashire. The FEI is involved with many of the above in testing equestrian surfaces. Through years of perfection, we have dedicated everything to developing not only a well-tested product, but a well-trusted network of professionals to take care of our clients from start to finish.

Visit our website www.footingfirst.com for more information and research articles.

Put Your Footing First: How to Care for a FootingFirst™ Arena

Our goal at FootingFirst™ is to install beautiful, functional arenas that will perform for decades. We do our best to make sure our customers’ footing is suited to their location and needs, and anyone with a FootingFirst™ arena knows that we stand behind our installation and products. However, even the most user-friendly footings require regular maintenance by the owner, and annual service by a FootingFirst™ professional. Below, we provide a guide on how to maintain an arena in a manner that will ensure longevity, proper performance, and above all, the safety of the horses and riders.

Tips for Regular Grooming:

Make sure you have the right harrow for your footing: If you don’t have the right harrow for your footing you’re going to have major issues. Plain sand footing (or western-style footing) uses one type of harrow, and footing that has fiber blended into it uses a different type of harrow.

Choose the proper vehicle: If a tractor with a three-point hitch is available, we highly recommend a harrow that operates off a three-point hitch. A quad or a UTV type vehicle is fine if a tractor is not available, and there are all kinds of harrows that work on those types of vehicles perfectly well, but a three-point hitch is the best. A busy facility with many horses should definitely consider a tractor and three-point hitch system.

Maintain the harrow: A harrow requires grease, cleaning, and general maintenance. Order teeth and tines for the harrow in advance. Have a spare set ready to go, and don’t wait until they wear out to replace them. If the harrow has pneumatic tires, make sure the tires have the proper air pressure, as a flat tire on one side will make the harrow lean to one side. The same goes for tractor tires. If a tractor tire is flat, again, the harrow will lean to one side and drag incorrectly.

When grooming an arena, allow for enough time: Sometimes an arena needs ten minutes of grooming, and sometimes it needs thirty minutes to get the footing in the right place. But when grooming the arena, give the footing what it needs. Don’t expect to do the same thing every day for months on end and have the footing be maintained properly. Sometimes it needs more work.

Grooming pattern: There are all sorts of strategies, but the most important part of grooming is that it’s not done the same way each time. Use a common-sense pattern, and change it up once in a while. Tight circles can be used to loosen the footing if necessary, but they should not be used every day.

No speeding: When grooming, don’t drive too fast. The inner tractor tire compresses in the corners and makes the footing uneven; you get the NASCAR effect, and the corners get too high. However, driving too slowly will lose the action on the spring tines. At the right speed they vibrate, and the vibration helps the footing flow right out from underneath the harrow, and you get a nice fluffy, even footing.

Don’t groom more than necessary: Particularly on footing with fiber. Some farms groom frequently because they like the tidy look. However, grooming does wear the footing a little bit. It also tends to pull the fiber to the top, whereas the horses blend the fiber in. The more the horses turn the footing up, the more the fiber gets turned in. Obviously, footing should be groomed when there is a lot of traffic, a lot of footfalls, or it’s getting lumpy, but not just because there are a few footfalls across the arena.

Pull the edges and corners in each week: If performed by hand using a rake each week, this will be done in ten to fifteen minutes. If it is ignored for a month, or three or four months, then a rake isn’t going to cut it. Then you need a shovel. But if you stay on top of it, it’s not so bad.

In an outdoor, keep up with the vegetation: Any weeds around the edges need to be removed. Keep organics off the footing. Weeds need to be blown off when possible, and manure needs to be removed. A little manure or a few leaves mixing into the footing won’t cause any major issues, but over a ten- to twenty-year period, small amounts of organics mixing in add up to a lot. Manure does not adversely affect high quality footing any more than lower-grade footing. A lot of manure mixing into footing is bad for any footing. We often get asked which footing doesn’t require manure removal, and the answer is that all footing requires manure removal!

Don’t groom footing that is soaking wet or bone-dry: A tractor will sink in wet footing and cause issues, and that’s pretty obvious. However, a harrow will pull the fiber out of bone-dry footing, and that’s a bit less obvious. You don’t want to do that, so the proper amount of moisture is necessary in footing.

Consider the weather: Seal off an outdoor before rain to promote even drainage. Sealing the footing off with a roller is best, but even just grooming before a rain to remove footfalls helps with drainage.

Add footing as needed: Don’t wait too long to add footing. It’s not good for the base, or the horses, or the footing company selling the footing!

Jumps should be removed from an arena once a week: A lot of people don’t do it, but they should. Most barns are closed on Mondays, so the barns that do a good job take all the jumps out of the arena on Monday and the person doing the grooming spends a longer period of time grooming the arena and getting the edges and the corners where they belong. The rest of the week they’re grooming around the jumps.

Caring for Water-Dependent Footing:

Irrigate with the right amount of water: Sounds obvious, but you’d be surprised! It’s also important to water evenly and consistently. An irrigation system that soaks one area of an arena and misses another area will cause a lot of issues, and the longer it goes on the more issues you will have. Don’t water outdoor arenas during or after a heavy rain, or the arena won’t drain properly.

Invest in a moisture meter: It is a great tool to have! It helps to get a better understanding of how much moisture is ideal in an arena, because everyone has a different preference. Some people want more movement in the footing, and some want less. If you can get a read on how much moisture you prefer, then you can keep it consistent.

Be careful with water from a natural source: We don’t want to discourage pulling from a pond or a lake because it is possible, but there is a certain level of cleanliness that a water source should have. Pulling from an unclean source can put a lot of microbes into the footing, and over time they break down and compromise the footing.

Servicing Your FootingFirst Arena:

Have your arena serviced at least once a year: On average, once per year works well. There are facilities that are so busy that they need service more often, and we have customers that use their arenas so lightly and do such a good job on their own maintenance, that they can stretch it to every two years. However, one year is a good rule of thumb.

Plan ahead for service: Think of servicing your indoor when you’re using your outdoor, and think of servicing your outdoor when you’re using your indoor. We can’t always get there immediately if an arena needs to be serviced, especially in the spring!

Regular service will extend the life of your arena: The typical service involves laser grading. If there’s a false base, we have to loosen it. We pull the edges and corners in and remove any vegetation. Then we till the footing as close as we can to the base. Then we proof roll it, laser grade it again, and then groom it. We inspect the footing and make any recommendations for changes in irrigation, grooming, or the necessity to add footing. We also inspect the customer’s harrow while we’re on site. For an average arena, service takes six to twelve hours if we’re not adding any additional footing.

Safe and functional footing is an investment, and the better you look after it, the better it will perform. Contact us today at (914) 490 – 2592 to schedule your spring service!

Arena Footing: How to Protect Your Investment

Your arena footing represents one of the most valuable investments on your farm. Good footing provides proper drainage, absorbs concussion, and gives without too much movement or sliding, good stability and traction, and absorbs concussion. Most well-constructed arenas start out in just this way, but keeping them functioning like new can be a challenge, especially if they get a lot of hoof traffic or, as in the case of an outdoor arena, are exposed to the forces of Mother Nature.

We asked Karen Leeming, co-founder of Footing First, LLC (www.footingfirst.com), to share tips on preserving our investment. Karen is more than a footing expert. She’s an accomplished rider and was the manager of the Canadian Olympic Equestrian Team in 2000 and again in 2002 for the World Equestrian Games. Karen, together with her partner, Lawton Adams (construction specialist), were the official suppliers of footing to the 2009 Syracuse International Sporthorse Tournament and the 126th National Horse Show 2005 through 2010.

Qualities of a Superior Footing

If you’ve ever ridden on a poorly constructed or poorly maintained arena surface, you know what a footing shouldn’t feel like: boggy, slippery, too deep or too compact. So, what are the qualities of a superior footing? What is it we’re trying to achieve? “Footing should support the hoof both vertically and horizontally,” says Leeming. “It should achieve good cushion and stability without too much movement or becoming too firm. A superior footing is one that requires less maintenance than a traditional footing, but does not give out when a horse’s hoof pushes against it. In takeoff at a jump, for instance, the footing should give and allow for a slight slide forward, but not so much as to have the hoof dig in, creating a hole.”

The most important aspect of a superior footing is forgiveness, but it should not interfere with allowing for the natural movement of the horse. “Durability and consistency are important no matter what the footing,” says Leeming.

Start With a Good Foundation

There are as many construction styles as there are riders to ride on them. To discuss them all is beyond the scope of this article, but starting with a good foundation is critical to the lifespan of the arena and its surface.

“The base is the most important component,” says Leeming. “There are many options for materials and installation styles.” Your choices may depend on the local climate and even the location of your arena. Leeming considers the traditional stone dust base a good option, providing it’s installed with the right pitch and compaction.

“We also have what is known as a ‘free-draining’ base,” says Leeming. “A free-draining base uses clean stone and drains. This creates a base (especially good for an outdoor arena) that can withstand an amazing amount of rainfall and still offer good drainage. We had a hurricane here on the east coast last year, and our arenas with the free-draining bases were good to ride on the very next day after the storm.”

Leeming also recommends the “mat system,” which is thought to be one of the best when it comes to offering good drainage. The mat system also provides a safe and sure base for the horse while still offering excellent shock absorption.

“The underwater system is totally different from the mat system. “This system is almost like a swimming pool,” says Leeming. “The arena is dug down to a good sub base layer that is clean of any sharp stones or objects. A liner (made of a very strong material) is placed on top of the sub base. Perforated pipes are laid down in a pattern that allows for good water flow throughout the arena. Sand is then placed over the pipes with this irrigation surface below. In warm, dry climates, riding on this surface helps to release the moisture into the footing. This surface works well in dry climates, as it requires the least amount of water to keep it moist. However, this underwater system will not work where freezing occurs.”

Regular Maintenance is Critical

“Maintaining the arena footing is just as important as changing the oil in your car,” says Leeming. “If you don’t maintain it, you’ll have drainage issues, changes in depth, and inconsistencies throughout.”

Small fixes include: pulling in the edges of the arena to allow excess water to drain away; removing weeds and plants that grow around the edges; and staying absolutely on top of manure removal.

“You should pick up manure in any footing,” cautions Leeming, “not just the high-end footings. Manure is organic and will break down and turn to dust quicker than any sand. You’ll have dust problems if you don’t. Look at it this way: 10 years with 20 horses using the ring will generate enough manure to fill several dumpsters. You don’t want that in your footing!” Manure should be removed after every ride. Keep a rake and muck bucket handy so riders are encouraged to use them.

For the surface, Leeming recommends using a small garden trowel to check the depth of the footing randomly throughout the arena. Keep a small rake handy as well to keep footing in place on the takeoff or landing side of the jumps, around barrels, or anywhere footing is likely to be displaced. This daily maintenance prevents low spots from forming, which can wreak havoc on your base. Don’t overlook the area where instructors tend to stand. Even human traffic, if it’s an everyday thing, can compact the footing. If you use a drag or harrow in the arena, be sure to use gentle equipment and make sure the harrow operator is someone who knows how to do the job properly.

“There are many harrows (or drags) on the market, and many of them are too aggressive and can ruin an arena,” says Leeming. She recommends a freestanding harrow or one with wheels. These are more goof-proof. “If you use a harrow that does not have wheels, then you run the risk of dragging the arena too deep and hitting the base. If you do that, you’re in a lot of trouble.”

How often you harrow depends on how often you use the arena, how much traffic it gets, and what type of footing you have. “We recommend harrowing in a different direction each time,” says Leeming. “So, one day you might go lengthwise; another you’ll drive the harrow crosswise. A super tool for this is called a swivel hitch that allows the harrow to follow your tractor like a trailer. This swivel hitch allows for a much better finish.”

Solving a Dust Problem

Dust poses a serious health hazard for both horses and humans. Silica, a fine particle in sand, is All fine particles that become airborne can be damaging to eyes, lungs, and respiratory systems, as is the dust from various wood

products. Horses engaging in athletic activities like jumping, barrel racing, roping, or dressage, often require up to 30% more oxygen than a horse at rest, but those dust-borne particles make getting that clean air next to impossible. So, what can we do?

“Other than a quality, dust-free footing, there is no single answer to solving dust problems,” says Leeming. What you can do will depend very much on what materials are in the footing. “In the winter, magnesium chloride can be added for best results.”

Magnesium chloride (MgCl²), mined from ancient seabeds, acts as a humectant, drawing moisture from the air into the footing. Every ounce of magnesium chloride can hold up to four times its weight in water, so once you commit to using it, don’t water your arena lightly as needed. Heavy watering or rain will wash the magnesium chloride off the surface and into the base in outdoor arenas. An added benefit of magnesium chloride is that it prevents the moisture in your arena from freezing.

Some manufacturers offer a blend of biodegradable oils or petroleum-based products for arena dust control that can provide good results. Some of these offer long-term solutions, but be sure to get a warranty your supplier stands behind its products. Enlist the help of a reputable company before applying chemicals or oils to your footings. It’s difficult for the novice to get the ratio just right. Oils do emit an odor that some riders find offensive, but manufacturers are remedying this problem by adding scented oils to the lineup.

You can go the traditional route as well by simply watering the arena, but you’ll have to do it fairly often. Use a water-wagon or sprinkler system to cover evenly. “If you have an outdoor arena, enlist the help of a good irrigation

person who understands riding arenas,” says Leeming. “Usually, a golf course person company that does golf course irrigation will understand the amount of water needed for the outdoor arena, probably somewhere around 3,000 to 5,000 gallons of water per day for the average outdoor arena.”

Recognizing the Warning Signs of Trouble

The best thing you can do for your arena is to never ignore the warning signs of trouble. What are the signs your arena needs help? “If you notice any sort of build-up of footing,” says Leeming, “usually in the corners or when the track gets out of control and becomes a high spot along the edge, that’s a problem. When the footing starts to compact and get hard, when you find yourself harrowing a lot more than usual and are still not getting good results, or if you’re hitting the base on a regular basis, these are signs your arena needs repair.” Act now to avoid more costly repairs down the road.

“The biggest mistake I see are people who ignore the signs,” says Leeming. “They wait until they see the base material and then panic. I also see people using the wrong or a too-aggressive drag. Some of these drags can ruin an arena in one day. But, real problems usually begin with an improperly constructed ring or a poor choice in footing. When choosing new footing, make sure to look at existing arenas that have the footing you like. Ask your builder to see arenas that are at least four or more years old and are heavily used. Remember, most footing looks good when it’s brand new. It’s the test of time that will tell the truth.”

Protecting your footing now avoids costly repairs in the future and ensures the comfort and well-being of your horses. Be sure to properly maintain your arena so that you can enjoy it for years to come.

Improving Existing Footing

How you can improve your existing footing will depend on the materials you have invested in and the problems you’re experiencing, but there are some standardized rules. Let’s take a look at what you can do to fix some common problems. First and foremost, determine if your base is in good shape. Don’t even think of investing in more footing materials if you’ve got a damaged base. You’ll be throwing good money after bad. Enlist the help of an experienced arena builder. He or she can determine if the foundation needs a bit of repair or if you’re looking at a complete overhaul. If the base needs work, the footing will have to be removed first. You might find you’ll need to add more footing material once the work is done.

If your base needs minimal repair, maybe you’ve got just a few holes or pockmarks, you could pull the footing back and fill those areas with new base material. Rent a compactor from an equipment supply center to get it good and solid. Coat the edges of all holes with a sealant (driveway sealer works fine) so the edges won’t crack or split if it gets wet. When the surface footing is damaged (pulverized or degraded), your builder might suggest removing half of the surface material to add new. Always talk to an arena expert before choosing to add footing because, once again, you’ll want to be sure that base is solid before making the investment.

Boggy or too-deep areas usually indicate a problem with drainage. This can be due to a poorly constructed base that was improperly graded in the first place. If it’s a small problem, simply raking in the edges can allow excess water to escape from the sides of the arena. Areas that are too soft may need an application of moisture.

The most important thing you can do to maintain your arena is to avoid repairs build it right in the first place. Do routine checks of your arena and don’t ignore problems when they occur. The soundness and well-being of your horses depend on it.

A Guest Post by Outside Rein: The Low-Down on High-Performance Footing

In addition to an extensive grasp of horsemanship, any serious rider can be expected to be aware of two things: first, the weather; and second, the quality of the ground upon which he or she is standing. At Outside Rein, we know that any athlete who is familiar with slippery, unforgiving, or uneven terrain is aware of the risks these circumstances pose, and this is especially true when they are beneath the hooves of a horse. The ride-ability of the ground is always top of mind for equestrians, and for those lucky enough to knock around in their very own ring at home, arena footing commands considerable attention.

The foundation of a safe and healthy arena requires more than just a few truckloads of sand. Recent advances in the systems, materials, and maintenance are complex, so this week we spent a significant amount of time picking the brain of footing-expert-to-the-stars, Lawton Adams, the co-founder of FootingFirst, and “ring-master” for some of the biggest pros in the biz. Below we share every dirty detail, including the busting of some pervasive myths, which we hope you will find useful whether you are building or revitalizing an arena of your own, or just want to survey the land with an educated eye the next time you roll into an unfamiliar facility.

Hear what McLain Ward has to say about FootingFirst.

Click here.

For those who are looking to install or upgrade an arena at a farm, what is the starting point?

People should really start with a budget. For some reason, people really don’t want to do that, and some get offended by it, but if you don’t start with a budget you end up wasting a lot of time. If you were in the market for a car, what’s the first thing that you do? You’d define a budget. You’re not going to go look at a Ferrari if your budget is $40,000. So I try to get people to consider the budget first, then the number of horses that are going to be using the arena, as well as the frequency. Obviously, the discipline of use is important as well.

Sometimes early in a conversation, a customer will tell me that they have a budget of $30,000, and they have eighty horses and thirty lessons that happen every day. Right out of the gate that’s an issue, and I’ll have to tell them that the budget is not enough to buy footing or to build an arena that will properly sustain what they’re trying to do. On the contrary, if someone has two horses and a budget of $100,000, I might tell the person that they can lower their budget, unless they just want the best of the best regardless of how often it’s used. More important than what you spend, is ensuring that you get value for your dollar.

Okay, so we’ve arrived at a budget. What next?

The three criteria I consider are the grading, drainage, and base. These must be done properly, or there will forever be issues. People focus too much on the footing and not what is beneath it, which is equality important. I often see people throwing money at the footing, when they really should be putting money into the drainage and base.

Some of our clients have purchased preexisting farms with arenas. In these cases, sometimes we have to come in and start over from scratch. Other times, the preexisting arena might not be horrible, but also might not be ideal. This makes it very challenging for us, because we have to figure out if we can work with what is already there. In that case, we quite often give multiple options which include a full renovation of the arena in order to meet the proper specifications, as well as the option to work with what already exists and potentially save a client a lot of money. In the latter case, we make it clear that there could be some minor issues, such as some erosion during storms, or the arena requiring an extra day to dry out. The client will go back to the budget, weigh the pros and cons, and decide what they want to do to make an arena that is as suitable as possible.

For an arena with a properly installed base but footing that isn’t ideal, we could simply take that footing off and replace it with a footing that offers more stability, or cushion, or both. As long as the base is done properly, the footing is malleable.

An example of FootingFirst’s TravelBright™ signature footing.

Once the base is installed, and it’s time to decide on footing…

Footing is sand, and all of the other products that are being promoted are additives. The sand is what matters most.

A poor-quality sand is one that doesn’t have good stability. The number of fines in the sand (or lack thereof) and the shape of the individual grains are important. A grain that is too large or round (i.e. beach sand) will not provide stability. Silica sand is the best. I began building rings in 1984, and after I had been doing them for a while, people began to comment that they really liked our work and that we had some of the best footing, but that when they went to Europe, the footing there was better than anything they had seen in the United States. We researched that, and what we found was that Europe has a very steady supply of silica sand, and they don’t have to go far to find it. They like to brag that they do footing better, and I agree with that to a point, but they’re also fortunate in their availability of sand.

In this country, depending on location, the nearest high-quality silica sand might be 400-500 miles away. Then, not only is it far away, but it can be very expensive to purchase. In other cases, it can be reasonable to buy, but if it has to be trucked several hundred miles it becomes exceedingly expensive (sand is heavy!). There are decent quality non-silica sands, but how well that will work in any particular situation is dependent upon the intended use.

Please tell us a bit about synthetics.

First, it needs to be said that fiber is not footing; fiber is an additive. There are several companies that market online that have been very successful selling fiber. They use the term “footing,” but often times once the order is placed, the fiber shows up and customers realize they have to add sand to it. Then the problem is that the sand wasn’t in the budget, and worse, they’re susceptible to getting the wrong sand. Sometimes they get lucky, sometimes they don’t. It depends on the region that they’re in.

Dressage and jumping have gotten to a point where the footing is very similar, requiring good stability on top, as well as cushion beneath. Fiber provides both if it’s the right type of fiber blend and is installed properly. Rubber is also an additive. Quite simply, it creates cushion, obviously. I never recommend an all rubber footing. You’ll never get the stability that you really need, and you can decondition a horse with it. I also don’t recommend putting rubber in most footing blends to start with. Generally, rubber is best when added in very small portions over time as a footing starts to compact or tighten, or to become “dead.” That’s another key factor — never add a lot at one time, because you can always add but it’s very hard to take it away.

I believe most issues with synthetics stem from misuse: too much; the wrong type; or, quite often, the wrong type of sand. If you have the wrong type of sand, I don’t care what you add to it, you’re not going to have a good footing.

Please tell us about “dust-free” versus “water-dependent” footing.

Our dust-free footing is made up of multiple products, and precisely blended with a select paraffin. And not all paraffins are equal! Our indoor versus outdoor blends do vary.

I recommend dust-free for all indoors. Watering indoor arenas can create issues; it’s difficult to water consistently indoors, and if you don’t put water down consistently, it creates variations in the footing. The other problem is that watering systems can raise the humidity level in the summer in an indoor, are prone to freezing in the winter, and often get windows or walls wet which creates stains or mold. If a water-dependent footing is put in an indoor, I highly recommend an overhead irrigation system that waters almost like rain.

At the end of the day, given the cost of irrigation, is it cheaper to do dust-free footing than irrigation?

It all depends on the availability of water. For some reason many people start backwards, from the cost of the watering system. But what good is a watering system if you don’t have a water supply? If you have a private well, how many gallons does it put out? If you’re using public water, do you get charged by the gallon and what is that cost? If you subtract the cost of the watering system from the additional cost of the dust-free system, sometimes it’s very close. And again, with an indoor, it’s a great decision.

For an outdoor ring it’s a little different. Our dust-free surfaces outside do work well and we have many of them out there, but the slight disadvantages are that the dust-free footing is hotter in the sun, and can take a little more diligence to maintain.

Dust-free footing (left) versus a blend of silica sand and fiber.

Water-dependent footing is generally more budget friendly, right?

Sure. And if someone says they want to spend as little as possible, or that they’re looking at sand in their region, we will source a good quality masonry sand as close to their location as possible. Then we will weigh the pros and cons of that sand against a higher quality sand that comes from further away. If somebody comes to us and just wants the best water-dependent footing that they can get, then we already have predetermined, high-quality silica sand and fiber blends on hand.

Is there a general watering rule?

Absolutely. With water-dependent footing, it is often misconstrued that the water is just there to prevent dust. In a high-quality blend, the water acts as a binder and is integral to its performance. If it’s dusty, it’s already way past the point where it should have been watered. This is one benefit to silica sand, which retains some moisture. The fiber holds some moisture as well, but not to a great degree. Local masonry sand will never be balanced fully with additives. Additives can help retain moisture or stability, but they’ll never make a lower quality sand equal the performance of a higher quality sand. Again, the key component of footing is the sand, not the additives.

Does geography play a large part in arena surface functionality?

Nothing is winter proof. If anyone ever tells you they offer winter proof footing, well, buyer beware! The only footing that we offer that is winter resilient, is the dust-free option. Because it absorbs the sun, the snow melts off of it faster, it loosens up faster, and it gets less deep of a freeze than other surfaces. Other than that, pretty much every base and every type of footing is going to have the same reaction to cold weather.

So we’ve talked about base, sand, additives, irrigation…is there anything else we’ve missed?

Well, maintenance, or grooming. First, don’t buy a groomer before the footing! Choose the footing first, then the tractor, then the harrow. I’ve had situations in which people have large arenas and a lot of square footage to groom, and they buy a little tiny garden tractor. I’ve had other situations in which people have a little tiny arena, and they buy a 60HP monster. Make sure your tractor and harrow match the footing and size of the arena.

The amount of arena grooming required is dependent on the footing. A footing that compacts easily will require more dragging, which also means burning more fuel, more wear and tear on your tractor, worn out teeth on your groomer, etc. It does add up. Dust-free footing generally requires less grooming, but of course all grooming depends on use and weather. As a rule of thumb, I always recommend grooming before a heavy rainfall to aid in consistent drainage of the arena.

We’ve talked about jumpers and dressage riders. What about western riders?

There should be crossover between jumpers and dressage riders. You might want to groom the same footing differently, but the right footing should be able to be shared happily by both. Western is a bit more complicated, specifically in regards to reining. Reining requires a completely different footing due to the sliding stops. The footing is there almost as a buffer, because when the horse slides it does so on the base, so reining requires a footing that will allow that to happen. It also requires a particular base that is compacted differently and has a different texture.

What are some common injuries that happen due to footing?

I’m not qualified to get into the physiological aspects of the horse, but I can get into the simple stuff. I do know that deep and loose footing (which are often the same), can create suspensory and soft tissue issues. A footing that is too hard or compacted can create sore feet, and bone or joint issues. Also, a footing that is too “grabby,” or that doesn’t have enough give on the surface, can create joint issues, especially over time. As a horse turns, the footing should give a little bit, and that’s actually the most difficult part of a footing to create. It should have stability so it doesn’t sheer, but also needs to give enough that it’s not putting stress on the horse’s joints. When dust-free footing was first on the market, it was firm and compact, which is what the equestrian world wanted. However, people started to realize this was not great. We have over time worked on creating better shear and cushion, but keeping good traction and stability in the blend.

How can you visually identify a footing as decent or poor before you get on and ride at a new location?

Someone with experience in footing can do a toe test by simply jabbing a foot into it, but that’s a skill that develops over time. It’s obviously not an exact science, but it’s a good start. And depth is central. Of course, optimal depth depends on the footing, but a local masonry sand shouldn’t be deeper than two to two-and-a-half inches, while a higher-grade footing can be as deep as six inches. Consistency is very important, though. A horse will typically do better on bad footing that is consistent, than $100,000 of inconsistent high-grade footing. Consistent depth and performance are paramount.

Lastly, if you’re having a footing specialist to your farm, don’t groom the footing before they get there. It happens to me all the time, but I need to see the penetration of the hoof. I need to see footfalls!

Very special thanks to Lawton Adams for sharing his expertise!

Footing Fiction vs. Fact

Misconceptions are widespread. Lawton Adams sets the record straight.

Fiction: “White sand makes the best footing.”

Fact: The color of sand has nothing to do with how it will perform when used for footing.

Fiction: “I have a fiber footing.”

Fact: Fiber and rubber are not footing; they are footing additives and only help when used for the right reasons and are properly installed.

Fiction: “Fiber will prevent dust.”

Fact: Fiber adds a minimal amount of moisture retention; it will not prevent dust.

Fiction: “Sand should be installed at least four inches in depth.”

Fact: Sand alone should never be installed at more than a three-inch depth and often not more than a two-inch depth depending on the type of sand.

Fiction: “You can always laser grade the footing in an existing arena.”

Fact: Footing can only be laser graded when it’s installed over a base that was laser graded.

Fiction: “You cannot drive heavy equipment or trucks on the arena.”

Fact: If this is true, then the arena was not properly built.

Fiction: “The base needs to settle before you can install the footing.”

Fact: This is only true if the base was not properly installed.

Fiction: “An outdoor arena should be built flat.”

Fact: If so, then you are asking for drainage issues.

Outside Rein is a service with a unique point of view, delivering a variety of equine-related topics to your inbox every Friday. If you’re not signed up, please do! They frequently offer exclusive discounts on products you’ll love, but only to their email subscribers.

Geo Textile Fibers

Geo textile carpet fibers and recycled fibers make up the new age of footing. Fibers have been used for many years in footing and turf to help strengthen and stabilize the footing. However, after many years of trial and error with different types and applications of fiber, the final years of real research and development have us on the cutting edge.

Since there are many different types and sources of fiber, we have found that at times often a blend works best. Fairfield Hunt Club has had great success with their outdoor arena, again this year the footing received rave reviews, from riders, trainers and the course designer.

Quality fiber blends can be used as an amendment to improve cushion and stability in existing footing. This is best achieved by using the correct sand, which should be angular in shape and extremely fine in texture. It is also important to recognize that the type of blend used and the installation of the blend are integral for achieving the best results. Geo textile and strand fibers cut at the correct length and size have proven to help most any footing; when blended into the sand, the fiber creates a consistent and forgiving surface. The Geo textile fibers can be mixed with high quality Silica Sand onsite but an experienced operator should always do this. Silica Sand and fiber have proven to be popular in the horse show world. However, too many of a certain type of fiber will create a footing that is very firm without any give; there is a fine line for these blends.

Fibers help to rejuvenate and stabilize an old footing, which will then add life to the footing instead of having to replace the footing. Adding fibers to existing footing creates cushion without depth, which is the biggest bonus that fibers provide.

It is also important to note that when producing new footing, sand and fiber alone will not make a quality footing; however, the proper blend engineered to the discipline of the user will create a footing that has tremendous traction, stability and cushion while having very good durability and low maintenance.

Fibers are an additive; they will help extend the life of an older arena by not needing to add additional sand causing more depth, therefore fibers are a great additive, with additive being the correct word of choice. Fibers a re not a footing; they are an additive that when used and installed correctly can help create a very good footing. We can improve your old footing or create a new footing that will last for many years.

Lawton Adams, a partner in FootingFirst, LLC, has been using fibers for the last 20 years (?) in many of his footing blends. The footing industry has followed many trends some better than others. At the moment adding fiber is one of the best cost-effective additives on the market and is proving to be an excellent trend. FootingFirst has many cost-effective ways to improve your arena. Obviously, our most popular dust-free footing TravelRight is also one of our best footings, offering excellent traction, stability, cushion and longevity. Now over ten years old, this footing blend has been improved upon tremendously due to all of our research and development.

FootingFirst, LLC offer’s many different types of footing from completely dust free to some of the best sand and fiber blends. Please feel free to contact us for more information.

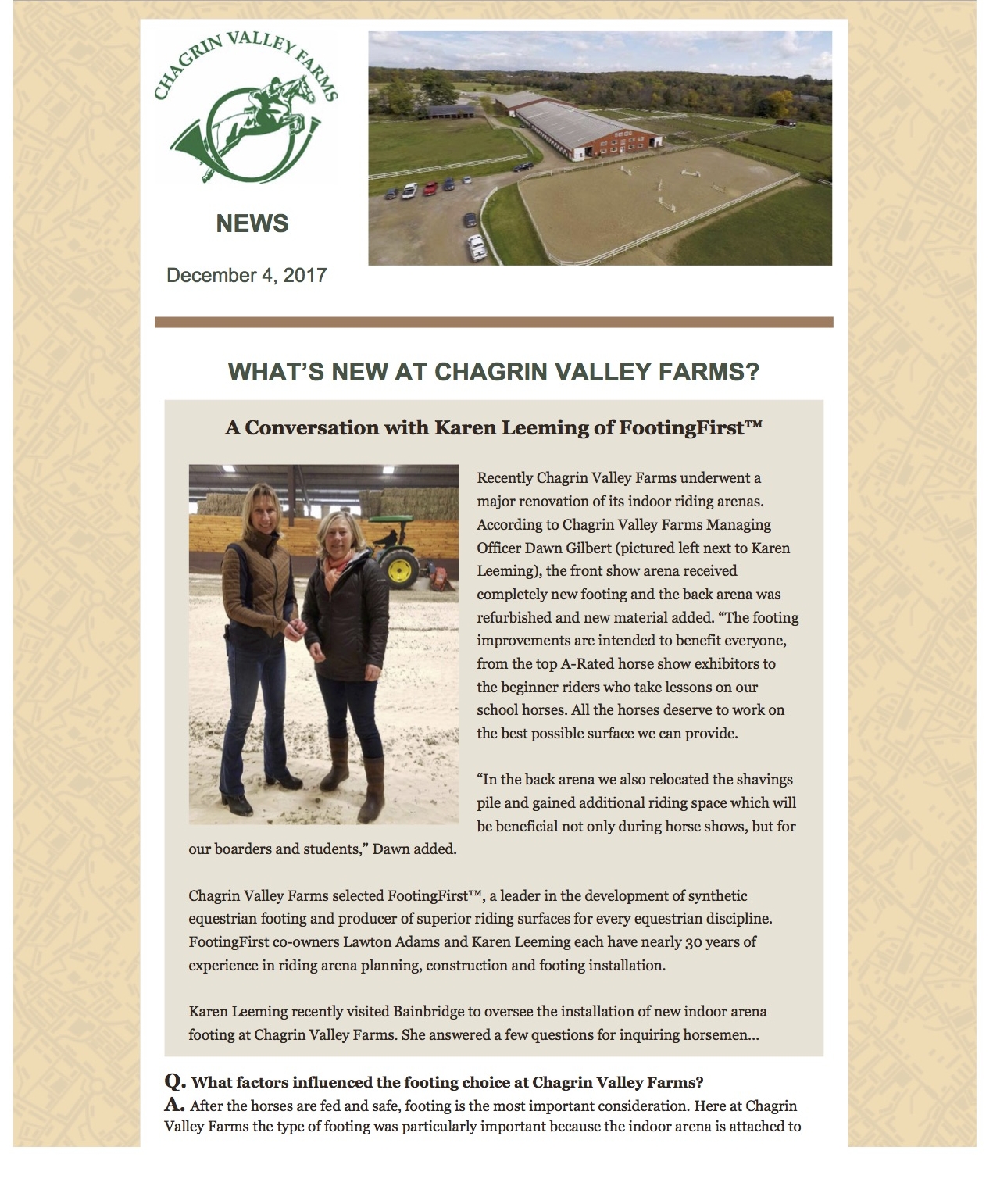

Chagrin Valley Farms & Footing First